ATEX-compliant sensors: More than just the probe

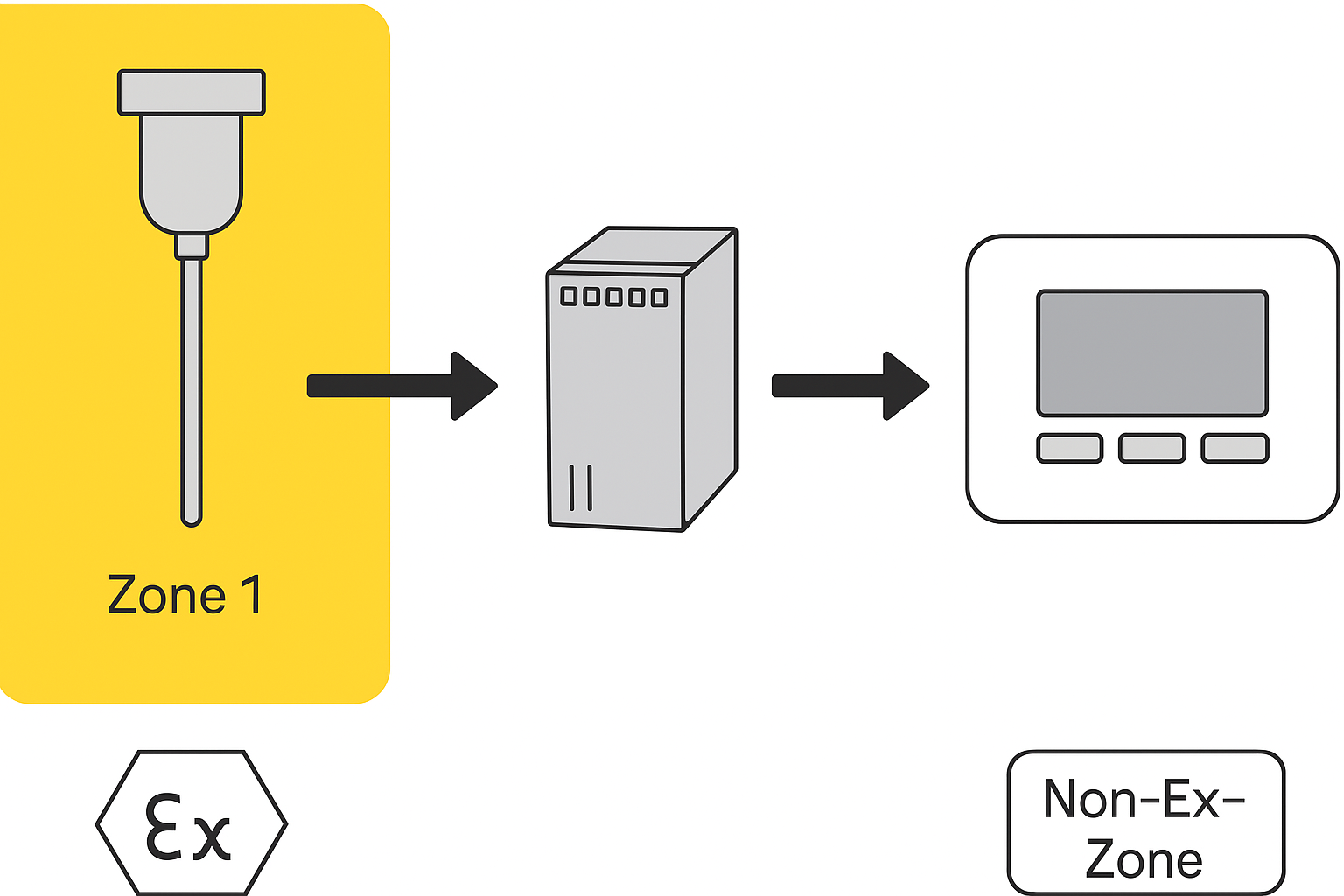

When measuring in Zone 1 or Zone 2, the first thing that often comes to mind is the actual sensor. An Ex-marked temperature probe? Check. A pressure transmitter with ATEX approval? Check. But what happens to the signal after that?

The reality is: the sensor is only half the story. It sends signals via cables to evaluation units, controllers or process control systems – and that is precisely where the often-underestimated source of danger lies.

Energy transmission in the Ex area – the underestimated risk

Even if the electronic measuring equipment is installed outside the Ex area, it transmits energy to the hazardous area via the signal or supply cables. This is not a problem in normal operation, but in the event of a fault (e.g. short circuit or defect), dangerously high energy can enter Zone 1 or 2. This can lead to the ignition of an explosive atmosphere.

The ATEX directive therefore requires that devices installed outside the Ex area must also be designed safely if they are connected to devices in the Ex area.

Example: Temperature probe in zone 1

A typical case:

- A Pt100 probe with Ex ia approval measures the temperature in a pipe.

- The cable leads to the electronic measuring system in the control cabinet, outside the ATEX zone.

- Without intrinsically safe isolation, these electronics can conduct dangerous voltage into the Ex area in the event of a fault.

The solution: Einsatz einer Zenerbarriere oder eines galvanisch getrennten Trennverstärkers mit ATEX-Zertifizierung.

The solution: Einsatz einer Zenerbarriere oder eines galvanisch getrennten Trennverstärkers mit ATEX-Zertifizierung.

The right solution: intrinsically safe circuits (Ex i)

The safest option for measuring systems in Zones 1 or 2 is the intrinsic safety (Ex i) concept. Here, the energy that enters the Ex area is so severely limited that no ignition is possible even in the event of a fault.

This includes:

- A sensor with Ex i approval (e.g. Ex ia IIC T4)

- An ATEX-certified barrier or isolating amplifier

- Electronic measuring equipment suitable for intrinsically safe circuits

The system is only truly safe – and standards-compliant – when all components work together.

Conclusion: ATEX safety thinks in terms of systems – not individual components

A single ATEX-certified sensor is not enough. Only by considering the measuring chain as a whole – from the sensor to the signal transmission to the evaluation – can safety in potentially explosive atmospheres be ensured. Whether temperature, pressure or level: the measuring electronics must also be ATEX-compliant or connected via intrinsically safe interfaces.